Don’t Let Pipe Lagging Hold Up Your December Projects

December is a busy month for project managers, contractors, and building owners — but it’s also a tricky time for construction schedules. Many teams start winding down for the holidays, trades go on leave, and council inspections slow down. In this environment, any delays caused by overlooked or incomplete pipe lagging can quickly cascade into costly reworks, failed inspections, and post-handover headaches.

December is a busy month for project managers, contractors, and building owners — but it’s also a tricky time for construction schedules. Many teams start winding down for the holidays, trades go on leave, and council inspections slow down. In this environment, any delays caused by overlooked or incomplete pipe lagging can quickly cascade into costly reworks, failed inspections, and post-handover headaches.

For medium-to-large commercial or multi-residential projects, having your pipe lagging sorted before the holiday period is crucial. Properly specified and installed thermal, acoustic, and fire-rated lagging ensures your mechanical systems — from hot and cold water to chilled water lines — remain compliant and perform efficiently from day one. It also protects your insulation from damage and condensation, reducing the risk of maintenance issues over the summer break.

If you’re finalising contracts or planning construction milestones in December, now is the time to lock in your pipe lagging. Early involvement with specialist installers ensures the right materials, thicknesses, and cladding options are in place, preventing costly delays and keeping your project on schedule.

Why December Is a Critical Time for Pipe Lagging

Many construction teams slow down in December. Contractors take leave, inspections are delayed, and project timelines tighten as everyone looks toward the holiday break. This makes December both a risky and opportune time:

- Rushing lagging work at the last minute can compromise quality and compliance.

- Delays in inspections mean that any unfinished or faulty lagging could push handover into the new year.

- Supply chain issues over the holiday period may limit access to specialised materials like closed-cell foam, mineral wool, or cladding systems.

By planning your pipe lagging early and ensuring it’s installed correctly, you remove a major source of potential delay and guarantee that your project is inspection-ready — even during the busiest month of the year.

December Contract Reminders: Don’t Overlook Your Lagging Requirements

Many businesses, contractors, and facility managers finalise contracts in December, either preparing for projects that will start in the new year or rushing to complete ongoing builds. This period is the perfect reminder: don’t let pipe lagging be an afterthought.

Ensuring your pipe lagging is correctly specified, sourced, and scheduled now will:

- Reduce the risk of post-holiday inspection failures

- Prevent last-minute delays caused by missing or incorrect materials

- Maintain energy efficiency and performance across all systems

- Protect your project’s budget and timeline

By planning ahead, you can enjoy the holiday season knowing your build is on track and compliant.

The Risks of Overlooking Pipe Lagging

In large commercial builds — from hospitals and data centres to multi-unit residential developments, missing or inadequate pipe lagging can cause a range of issues:

Thermal inefficiency: Hot and chilled water systems lose energy without proper insulation, leading to higher operational costs.

Condensation damage: Cold water or chilled systems that aren’t correctly lagged can develop surface moisture, causing mould, corrosion, or water damage to walls, ceilings, and other services.

Acoustic problems: Plumbing noise travels quickly in multi-residential and commercial buildings, disturbing tenants or staff. Without acoustic lagging, complaints and remediation works become common.

Compliance failures: Section J of the National Construction Code (NCC) sets minimum thermal performance standards. Improper or unspecified lagging can lead to failed inspections, delaying project handover and costing time and money.

These issues aren’t just “minor inconveniences” as they can derail schedules, add unplanned costs, and damage your reputation as a project manager, contractor, or developer.

Why Getting It Right Early Matters

It's crucial to plan and install your pipe lagging early. By locking in specifications and installation before or during December, you:

- Ensure the right materials and thicknesses are selected for each system, whether it’s hot water, cold water, or chilled water lines.

- Integrate acoustic and fire-rated lagging where required, ensuring compliance and occupant comfort.

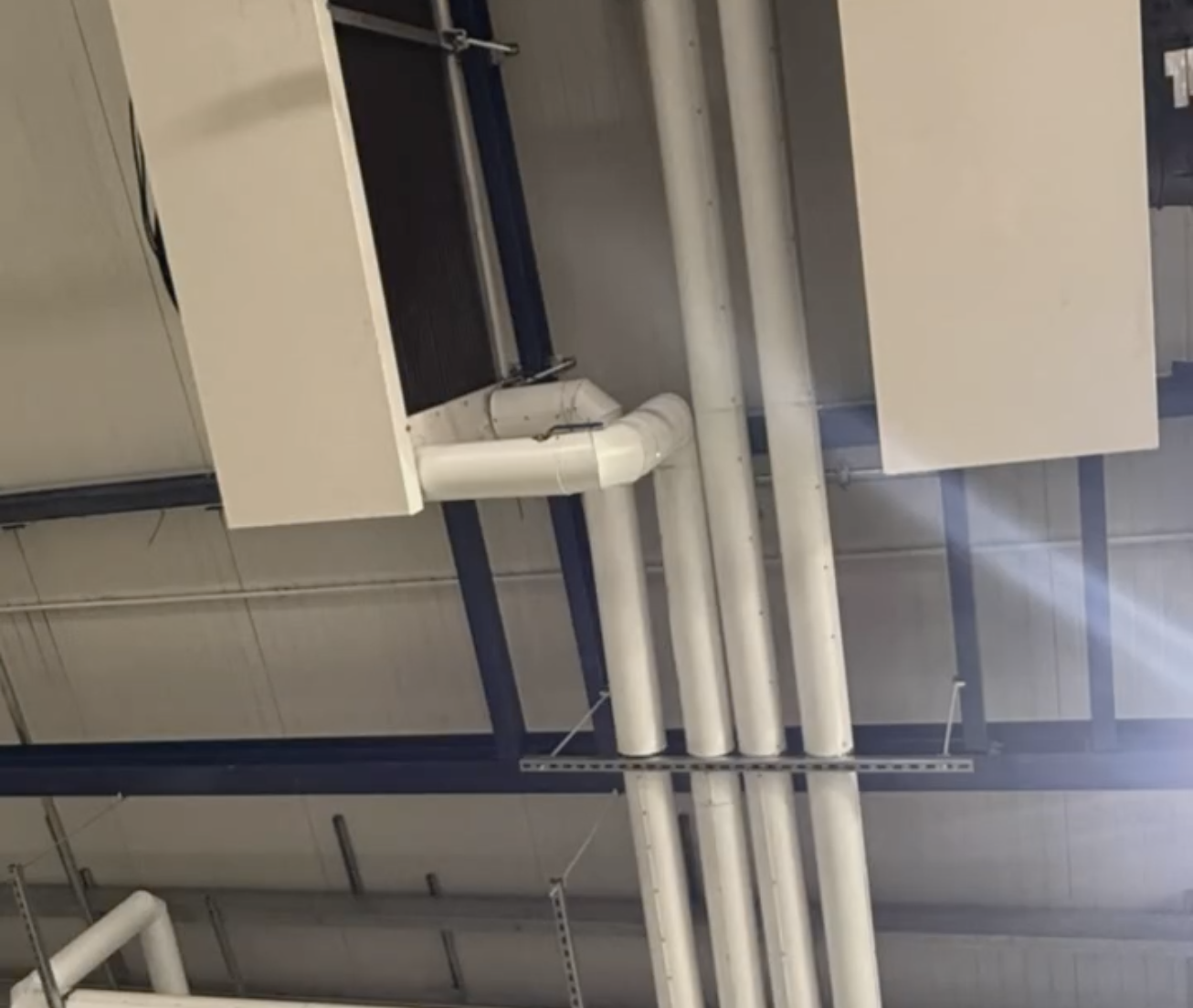

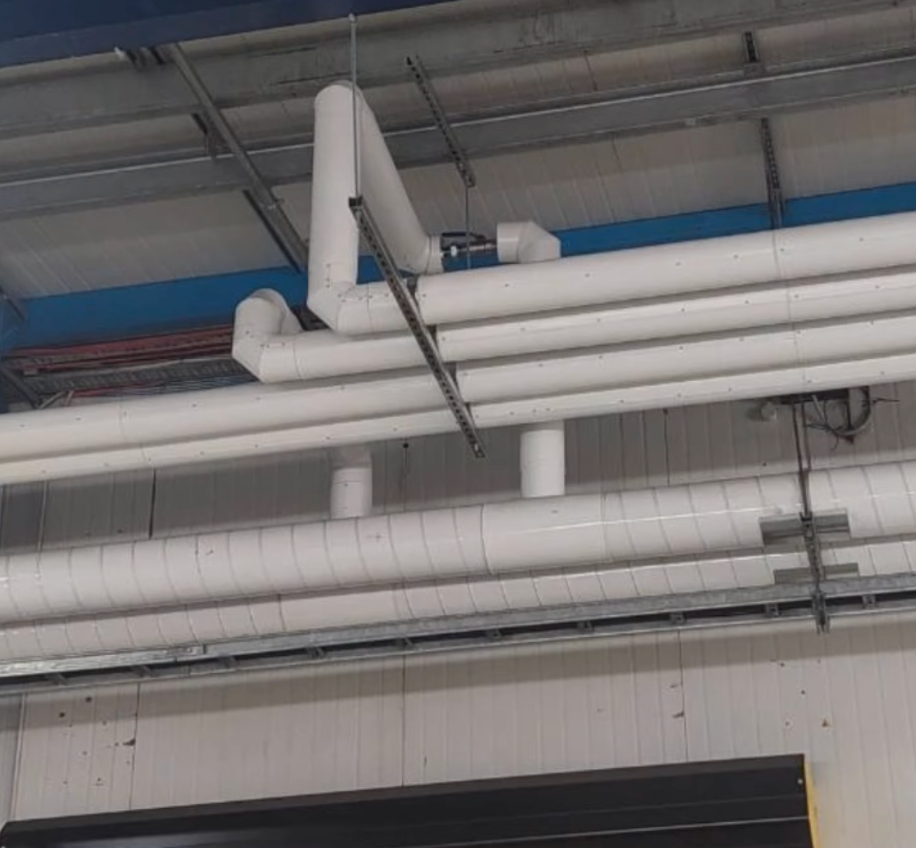

- Protect lagging with cladding, like aluminium, stainless steel, Colourbond, or PVC, for mechanical protection, moisture resistance, and durability.

- Avoid last-minute rework, keeping your project on schedule and your inspections stress-free.

Working with an experienced lagging specialist guarantees that specifications are accurate, materials are appropriate, and installations are executed correctly the first time. This not only protects your build but also simplifies the documentation and handover process for certifiers and inspectors.

Lagging and Cladding: A Combined System

It’s important to remember that lagging alone isn’t enough. Cladding and lagging work hand-in-hand:

- Lagging provides the thermal, acoustic, and fire protection.

- Cladding shields the insulation from moisture, impact, UV exposure, and ongoing wear during maintenance.

Together, they create a system that performs reliably over time, meets NCC and AS standards, and prevents costly rework — even when projects are rushed or working around holiday schedules.

Why Melbourne Builders and Businesses Trust Martis Laggers for Pipe Lagging

With over a decade of experience, Martis Laggers specialises in pipe lagging, acoustic insulation, thermal insulation, and protective cladding for Melbourne’s largest commercial and multi-residential projects. Our team works with builders, contractors, and facility managers to deliver:

- High-quality lagging installations for hot, cold, and chilled water systems

- Tailored material selection, including closed-cell foam, fibreglass, mineral wool, and acoustic composites

- Durable cladding solutions to protect insulation and enhance long-term performance

- Full compliance documentation to streamline inspections and handovers

Don’t let poor lagging planning hold up your December projects. Get in touch today and make sure your insulation and cladding are done right the first time, so you can enjoy Christmas without last-minute building headaches.

Disclaimer

This article is provided free of charge for public information. We do not guarantee, and accept no legal liability for, the accuracy, reliability, currency, or completeness of the content or any linked material. Users should apply their own judgment and verify the material’s relevance to their needs. This article is a general summary and not a substitute for legal or professional advice. Users should seek appropriate advice for their circumstances. Any third-party views expressed do not necessarily reflect ours or imply endorsement.